|

The proposal and the development of the on-line calibration system for HEC calorimeter is one of the crucial tasks.

In order to achieve an optimal energy resolution of the calorimeters it is necessary to develop

a system to calibrate the gain variations in the

The first prototype of a calibration pulse generator was developed by our institute.

We used a specific integrated circuit (ASIC) (CMOS technology with a

structure length of 1.2

The calibration system was developed and tested several time - in 1999-2002 -

combined EMEC/HEC, and in 2003

combined EMEC/HEC/FCAL and HEC/FCAL tests.

In Fig. 1 you can see the calibration signal (left) and

the prediction for the ionisation signal (right) together with the

residuals with the respects to the fit (lower figures).

In 1998 the Cleland method for the noise suppression in the calorimeter readout was successfully applied by our group. The improvement of the signal/noise ratio can be seen in Fig. 2.

In Fig. 3 is shown the linearity in the four different impact points in the test modules with the points corresponding to uncalibration and calibration data for the various electrons energies. The improvement is markant.

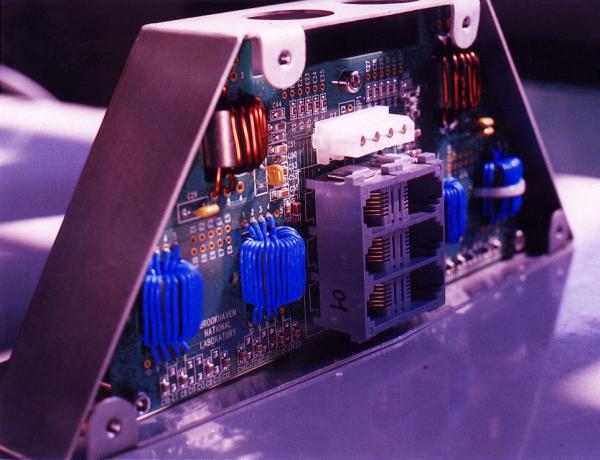

is going to be used for the EM and HEC part of the Atlas calorimeter. As described in the TDR of the liquid argon (LAr) calorimeter, the FEBs contain the electronics for amplifying, shaping, sampling, pipeling, and digitising the LAr calorimeter signals. The FEB electronics e.g. must handle the signal dynamic range of about 16 bits without contributing more than 0.2%. On the Fig 5 the FEB test setup at Buld. 180 is shown.

all needed quality criteria.

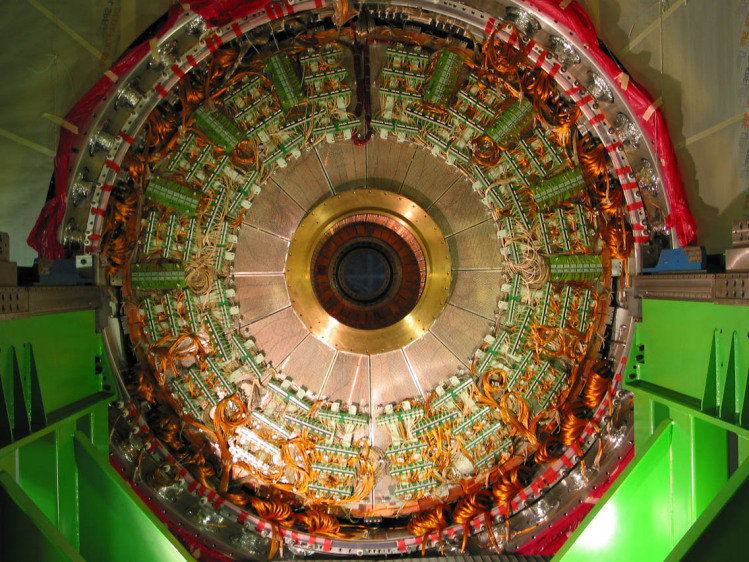

the ATLAS barrel cryostat with our filter boxes (see

Fig. 10 in more detail) is shown.

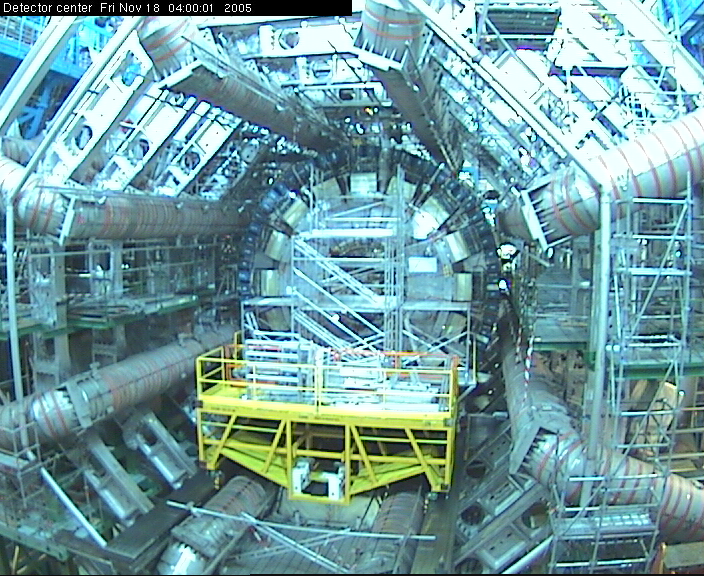

Now on the detector side, tremendous progress has been done: in building 180 for liquid argon (LAr) HEC (for both two wheels A, and C) the cooling, testing and after than the transport to point 1 in anticipation of its imminent descent into the pit has been done also. See also Fig. 12:

On the Fig. 13. the view into ATLAS pit with the Endcap wheels C is shown (November 2005).

|